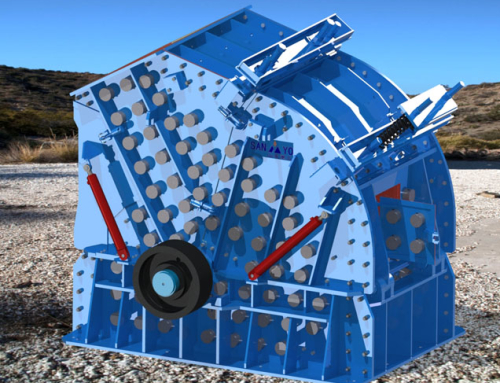

Project Description

- Strong and reliable structure.

- High crushing ratio with large output capacity.

- Wedge design setting adjustment which allows for the production of different sized material.

- V-shaped design allows for feeding of bulk volumes of large sized material into the crushing cavity where there are no dead zones, making this machine highly productive and very efficient.

- Lubrication system – safe and reliable, easy to maintain.

- Can be used in stationary or semi-mobile type.

- The eccentric shaft is fitted with four bearings,two on each side,S which extends service life.

| Model | Max feeding size (mm) | Min discharge size (mm) | Power (kw) | Crushing capacity (t/h) | |||||||||||||||

| End discharge opening size (mm) | |||||||||||||||||||

| 10 | 15 | 25 | 30 | 40 | 50 | 60 | 70 | 80 | 100 | 125 | 150 | 200 | 225 | 250 | 300 | ||||

| HV04 | 400×600 | 50 | 37 | 26 | 38 | 45 | 60 | 75 | |||||||||||

| HV05 | 500×700 | 50 | 55 | 40 | 60 | 70 | 90 | 112 | 130 | ||||||||||

| HV0509 | 500×900 | 50 | 75 | 45 | 72 | 85 | 100 | 130 | |||||||||||

| HV06 | 600×900 | 80 | 75 | 105 | 130 | 160 | 182 | ||||||||||||

| HV08 | 750×1060 | 100 | 110 | 180 | 210 | 237 | 294 | ||||||||||||

| HV09 | 900×1200 | 100 | 160 | 210 | 250 | 280 | 320 | 350 | |||||||||||

| HV10 | 1000×1200 | 125 | 200 | 265 | 302 | 370 | 402 | ||||||||||||

| HV0813 | 800×1350 | 100 | 220 | 250 | 300 | 340 | 420 | 450 | |||||||||||

| HV1015 | 1000×1500 | 125 | 220 | 310 | 350 | 440 | 480 | 510 | |||||||||||

| HV12 | 1200×1500 | 150 | 220 | 415 | 500 | 540 | 580 | 630 | |||||||||||

| Electrical requirement | 380 to 420V, AC(50/60Hz) or according to local standard | ||||||||||||||||||

| Temperature range | -50℃ to 70℃ | ||||||||||||||||||

| Lubricating system | Auto control lubrication oil station, accident alert | ||||||||||||||||||

| Dischargeable system | Hydraulic system | ||||||||||||||||||

| Raw material water content | ≤20% | ||||||||||||||||||

| Design Type | Euro Type | ||||||||||||||||||

| Crush method | Stone to stone crushing | ||||||||||||||||||