Teeth Roller, Welding Roller

– Roller Crusher Wear Parts

Teeth Roller is the main wear part of Roller Crusher, our material is high manganese steel with tungsten, tin, chromium and other rare metals. Very wear-resistant and high temperature resistant with can reach to HRC58~HRC63.

The hardness is the most essential factor of the products. Because of the advanced process, our teeth rollers contain a service life 50~100% longer than those made of traditional high chromium iron.

| Name | Teeth roller,welding roller, teeth roll, tooth roller, teethed roller |

| Material | Cr20Mn2,Cr26Mn2 |

| Control | Spectrometer chemical analysis and control while producing |

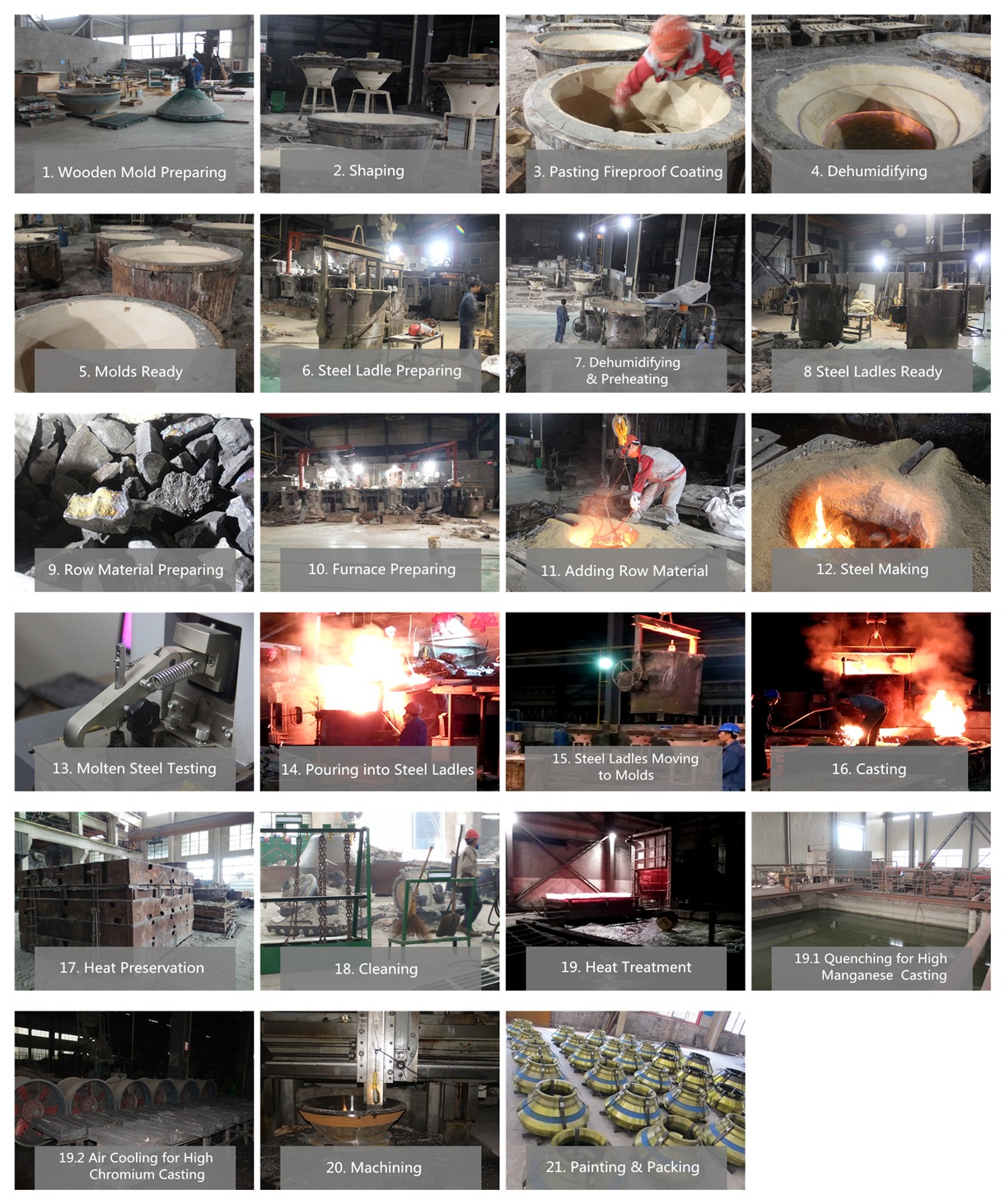

| Molding Process | Water-glass sand casting or lost form casting |

| Melting facility | Medium frequency electric furnace |

| Heat Treatment | Anneal, quenching, tempering |

| Quality Guarantee | None |

| Testing | Hardness, flaw detector test |

| Certificate | ISO9001~2008 Passed; BUREAU VERITAS |

| Application | Cement firms, coal fired power plant, mining firms, metallurgy, quarry firms |

| Packaging Details | As the clients’requirement |

| Delivery Time | 20~30 days after payment |

High Chrome Casting Material Chemical Composition(%)

| Designation | Hardness of Work Site(HRC) | Ak/cm | Working life (Other Products) | |

| High Manganese Hammerhead | Cast Iron Mill Liners | |||

| Cr15 | 50-60 | ≥30 | ≥1.5 | ≥5 |

| Cr20 | 58-62 | ≥30 | ≥2 | ≥5 |

| Cr26 | 60-65 | ≥30 | ≥2–3 | ≥5 |

![]() Mechanical property test report-Willing (Shanghai) Industrial Co.,Ltd

Mechanical property test report-Willing (Shanghai) Industrial Co.,Ltd

![]() Metallographic inspection report-Willing (Shanghai) Industrial Co.,Ltd

Metallographic inspection report-Willing (Shanghai) Industrial Co.,Ltd

![]() The spectrum test report-Willing (Shanghai) Industrial Co.,Ltd

The spectrum test report-Willing (Shanghai) Industrial Co.,Ltd

|

|