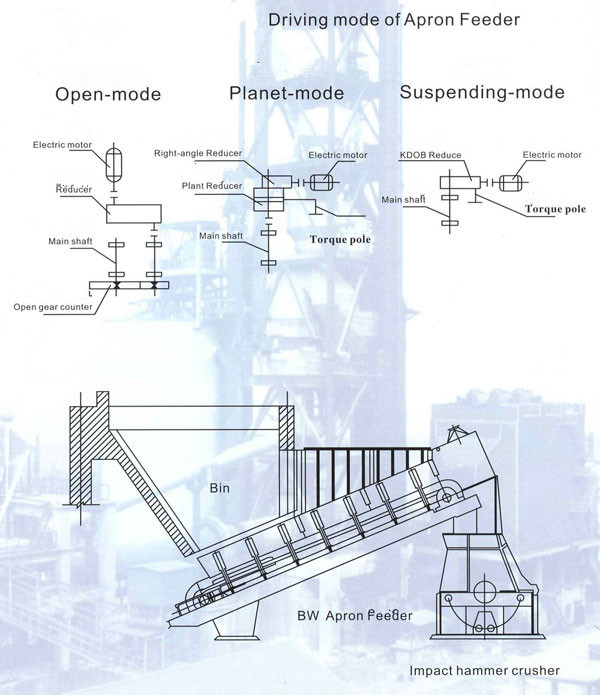

Heavy Apron Feeder

Heavy Apron Feeder is engineered for heavy-duty operation and for primary or subsequent application stages. These custom-built feeding machines are designed to suit individual requirements of capacity, size and material handled.

Willingindustry’s heavy apron feeder also has an integral matching scraper conveyor with built-in drive to handle spillage. This system ensures an economic layout and increased belt conveyor length vis-à-vis a conventional system with spillage chute. The feeders are specially designed to minimize maintenance. And widely used in metallurgy, chemical industry, coal, building materials and electric power and other industries.

PrincipleHeavy apron feeder consist primarily of two strands of endless tractor chain with either cast manganese or fabricated steel pans bolted to a common link of each strand. The chains are driven by sprockets that are mounted to a head shaft. The pans travel with the chain and articulate over the head sprockets to discharge material. Features1.Impact rails limit pan deflection under high impact conditions. BenefitsControlled feed rate; Incredibly reliable; Easily handles large, frozen or cohesive material; Few spare parts. FieldsHeavy Apron Feeder is one of the machines for continuously transporting materials. It is widely used to transport large-volume materials to various crushing equipments uniformly and continuously in a short distance. It is especially suitable for transporting large, high temperature and sharp materials, and it can reliably work in harsh and humid outdoor environments. |

|

| Model | Width Plate (mm) |

Distance Of Shafts (mm) |

Speed (m/s) |

Feed Size (mm) |

Capacity (t/h) |

Power (kw) |

Weight (kg) |

Overall Dimensions (LxWxH)(mm) |

| WL100-6 | 1000 | 6000 | 0.01~0.1 | <500 | 80~160 | 11 | 15000 | 86200x4960x1600 |

| WL100-12 | 1000 | 12000 | 0.05~0.1 | <500 | 60~130 | 15 | 23500 | 13500x4215x1675 |

| WL120-4 | 1200 | 4000 | 0.014~0.08 | <500 | 45~150 | 11 | 12600 | 5810x5160x1480 |

| WL120-4.5 | 1200 | 4500 | 0.054 | <500 | 150 | 15 | 30500 | 7183x3616x2071 |

| WL120-6 | 1200 | 6000 | 0.01~0.1 | <500 | 80~160 | 11 | 16000 | 8620x5160x1600 |

| WL120-11 | 1200 | 11000 | 0.01~0.1 | <600 | 50~100 | 15 | 23500 | 11463x5029x2860 |

| WL120-19 | 1200 | 19000 | 0.014~0.09 | <600 | 45~150 | 22 | 41000 | 21620x5460x2000 |

| WL125-6 | 1250 | 6000 | 0.014~0.08 | <600 | 45~150 | 11 | 18900 | 8620x5240x1950 |

| WL125-12 | 1250 | 12000 | 0.014~0.08 | <600 | 45~150 | 18.5 | 31800 | 14620x5460x2000 |

| WL140-8 | 1400 | 8000 | 0.017~0.17 | <700 | 100~200 | 22 | 29200 | 10350x5948x1840 |

| WL140-16 | 1400 | 16000 | 0.006~0.06 | <700 | 20~200 | 22 | 45900 | 18310x6447x2030 |

| WL140-18.03 | 1400 | 18030 | 0.006~0.06 | <700 | 20~200 | 22 | 50900 | 20380x6440x2030 |

| WL150-5 | 1500 | 5000 | 0.014~0.08 | <700 | 85~288 | 15 | 18700 | 7620x5440x1950 |

| WL150-10.5 | 1500 | 10500 | 0.006~0.06 | <700 | 20~200 | 22 | 49400 | 12850x5595x1705 |

| WL150-15 | 1500 | 15000 | 0.006~0.06 | <700 | 20~200 | 22 | 58800 | 17350x5595x1705 |

| WL160-6 | 1600 | 6000 | 0.017~0.17 | <800 | 61~610 | 22 | 25000 | 8354x6099x2100 |

| WL160-9 | 1600 | 9000 | 0.076 | <800 | 180 | 22 | 34700 | 11250x5716x2240 |

| WL180-8 | 1800 | 8000 | 0.022~0.046 | <1000 | 30~320 | 37 | 53000 | 10300x4295x3650 |

| WL220-10 | 2200 | 10000 | 0.018~0.055 | <1500 | 220~680 | 45 | 80400 | 12650x4495x3350 |

| WL240-10 | 2400 | 10000 | 0.018~0.055 | <1500 | 220~680 | 45 | 83400 | 12650x4695x335 |

|

|