Blow Bar, Impact Plate

– Impact Crusher Wear Parts

The main wearing parts of Impact Crusher are blow bars and impact plates, with special heat-treatment, the hardness of our blow bar can reach to HRC58~HRC63. The product mainly uses high manganese steel material, for example Mn14Cr2, Mn18Cr2, Mn22Cr2 and so on.

Willing’s blow bars and impact plates are widely used on mining, construction, chemical, cement and metallurgical industry. Our impact parts have a service life 50~100% longer than those made of traditional high chromium iron.

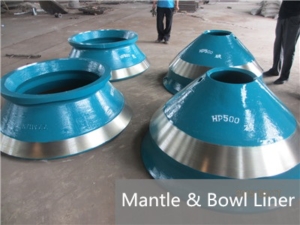

| Name | Blow bar, impact plate, side plate |

| Material | Mn13Cr2( M1 equivalent grades), Mn18Cr2(M2 equivalent grades) |

| Control | Spectrometer chemical analysis and control while producing |

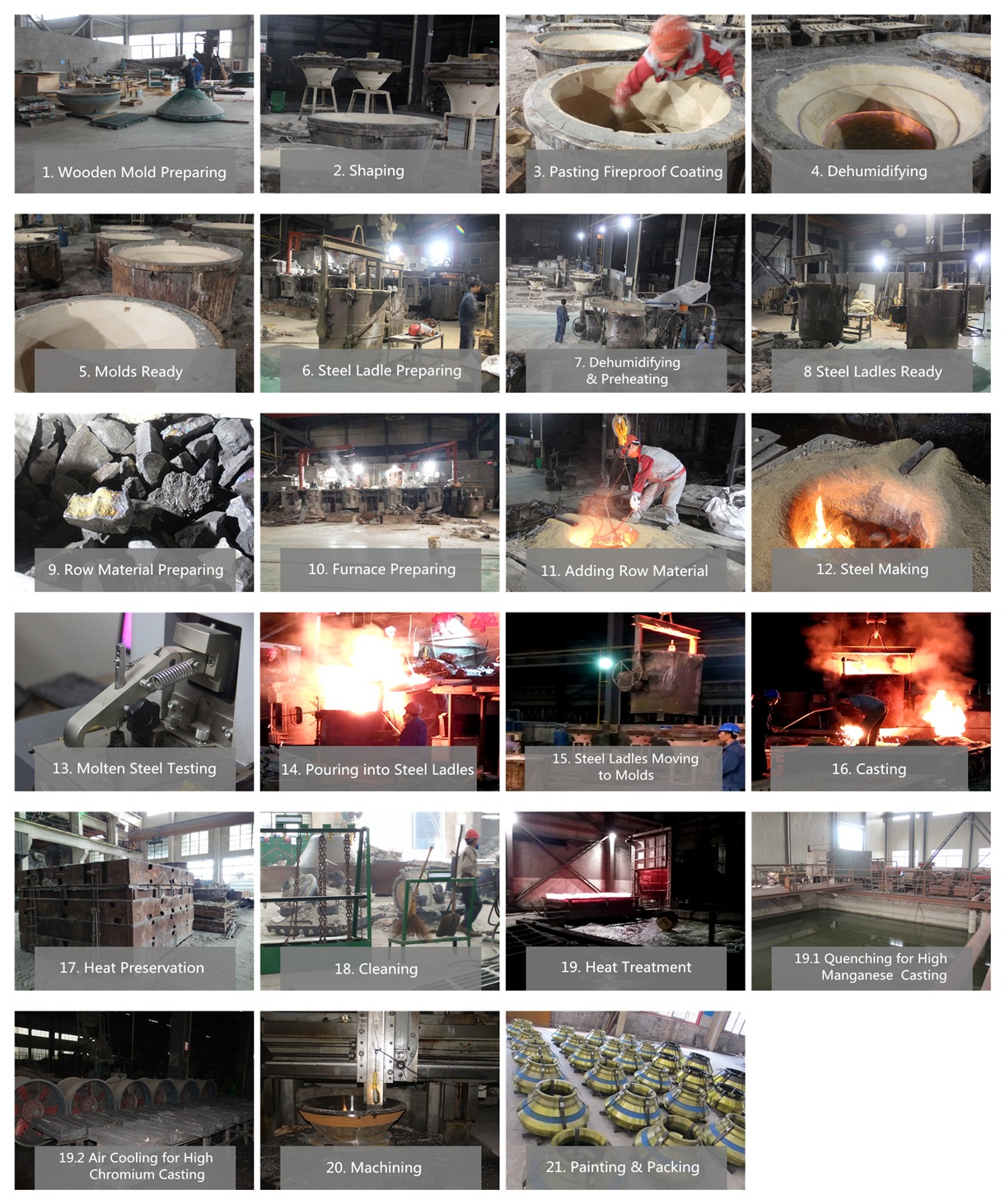

| Molding Process | Water-glass sand casting or lost form casting |

| Melting facility | Medium frequency electric furnace |

| Heat Treatment | Anneal, quenching, tempering |

| Quality Guarantee | None |

| Testing | Hardness, flaw detector test |

| Certificate | ISO9001~2008 Passed; BUREAU VERITAS |

| Application | Cement firms, coal fired power plant, mining firms, metallurgy, quarry firms |

| Packaging Details | As the clients’requirement |

| Delivery Time | 20~30 days after payment |

High Chrome Casting Material Chemical Composition(%)

| Code Elem. | C | Si | Mn | Cr | Mo | Na | Cu | P | S | HRC |

| KmTBCr4Mo | 2.5-3.5 | 0.5-1.0 | 0.5-1.0 | 3.5-4.5 | 0.3-0.5 | – | – | ≤0.15 | ≤0.10 | ≥55 |

| KmTBCr9Ni5Si2 | 2.5-3.6 | 1.5-2.2 | 0.3-0.8 | 8.0-10.0 | 0-1.0 | 4.5-6.5 | 4.5-6.5 | – | – | ≥58 |

| KmTBCr15Mo | 2.8-3.5 | ≤1.0 | 0.5-1.0 | 13-18 | 0.5-3.0 | 0-1.0 | 0-1.0 | ≤1.0 | ≤0.06 | ≥58 |

| KmTBCr20Mo | 2.0-3.3 | ≤1.2 | ≤2.0 | 18-23 | ≤3.0 | ≤2.5 | ≤1.2 | – | – | ≥60 |

| KmTBCr26 | 2.3-3.3 | ≤1.2 | ≤1.0 | 23-30 | ≤3.0 | ≤2.5 | ≤2.0 | – | – | ≥60 |

![]() Metallographic inspection report-Willing (Shanghai) Industrial Co.,Ltd

Metallographic inspection report-Willing (Shanghai) Industrial Co.,Ltd

![]() The spectrum test report-Willing (Shanghai) Industrial Co.,Ltd

The spectrum test report-Willing (Shanghai) Industrial Co.,Ltd

![]() Ultrasonic inspection of damage report-Willing (Shanghai) Industrial Co.,Ltd

Ultrasonic inspection of damage report-Willing (Shanghai) Industrial Co.,Ltd

|

|