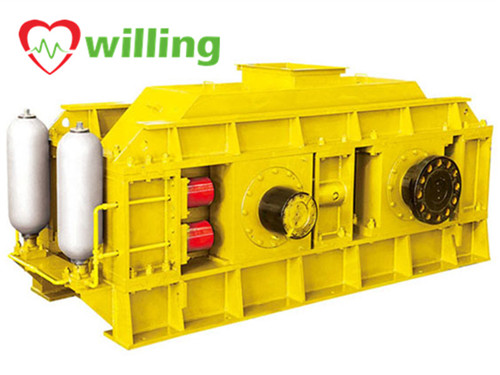

Double Teeth Roller Crusher

The Double Teeth Roller Crusher is of simple structure, reliable operation and low cost. It is widely used in middle and small sized mines for intermediate and fine crashing of the brittle and soft ores of intermediate hardness like coal and coke.

Double teeth roller crusher is mainly used for crushing rocks of medium or lower rigidity, such as coking coal, agglonerate, limestone, and so on. The crushing machine is most suitable for the mid-crushing and fine crushing work in non-metal mines of medium and small scale and chemical industries. The smalllest discharge granularity could be less than 100 meshes.

Also the roller crusher contains not only teeth roller crusher, but also welding roller crusher.

Double Teeth Roller Crusher

| Teeth Roller Model | Roller Diameter (mm) | Capacity (t/h) | Max Feeding Size (mm) | Discharge Opening Size (mm)(f=8) | Speed reducer | Motor | Weight (kg) | Overall Dimension (mm) |

| Ø900×600 | Ø600 | ~50 | <25 | <3, 72% | ZLY200-20-Ix2 | Y200L2-6 22KW x 2 |

7500 | 2250x3269x1060 |

| Ø1000×700 | Ø800 | ~90 | <30 | <3, 70% | ZLY224-20-Ix2 | Y225M-6 30KW x 2 |

14800 | 2894x3773x1285 |

| Ø1200×800 | Ø1000 | ~170 | <40 | <3, 65% | ZLY280-20-I ZLY280-20-IV |

Y280L2-6 55KW x 2 |

24500 | 3444x3637x1448 |

Welding Roller Crusher

| Welding Roller Model | Roller Diameter (mm) | Capacity (t/h) | Max Feeding Size (mm) | Discharge Gate Size (mm)(f=8) | Speed reducer | Motor | Weight (kg) | Overall Dimension (mm) |

| Ø600×400 | Ø600 | ~12 | <20 | <3, 75% | ZLY180-20-Ix2 | Y180L2-6 15KW x 2 |

4800 | 1690x1940x850 |

| Ø800×600 | Ø800 | ~25 | <25 | <3, 72% | ZLY200-20-Ix2 | Y200L2-6 22KW x 2 |

7500 | 2250x3269x1060 |

| Ø1000×700 | Ø1000 | ~40 | <30 | <3, 70% | ZLY224-20-Ix2 | Y225M-6 30KW x 2 |

14800 | 2894x3773x1285 |

| Ø1200×700 | Ø1200 | ~70 | <40 | <3, 70% | ZLY280-20-I ZLY280-20-IV |

Y280L2-6 55KW x 2 |

21500 | 3444x3537x1448 |

| Ø1200×800 | Ø1200 | ~70 | <40 | <3, 65% | ZLY280-20-I ZLY280-20-IV |

Y280L2-6 55KW x 2 |

24500 | 3444x3637x1448 |

| Ø1500×700 | Ø1500 | ~150 | <50 | <3, 72% | ZLY355-20-I ZLY355-20-IV |

Y315L2-8 110KW x 2 |

32500 | 4133x3970x1760 |

| Ø1500×800 | Ø1500 | ~150 | <50 | <3, 70% | ZLY355-20-I ZLY355-20-IV |

Y315L2-8 110KW x 2 |

35000 | 4133x4070x1760 |

| Ø1800×800 | Ø1800 | ~150 | <50 | <3, 75% | ZLY450-20-I ZLY450-20-IV |

Y355L2-8 160KW x 2 |

49000 | 4860x4208x2050 |

|

|