|

|

|

||

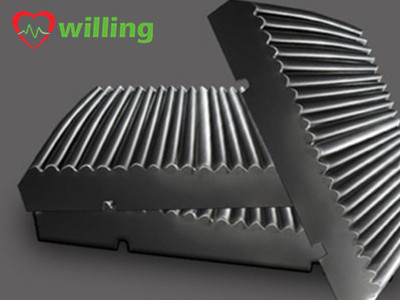

Jaw Plate |

Mantle, Bowl Liner |

Blow Bar |

||

| Jaw Plate is the main wear part of jaw crusher, including fixed plate and jaw plate . We can produce a variety of meet the requirements of the jaw plate according to the customer’s model . Because of the use of manganese content of 13% to 30% of the high manganese steel and ultra-high manganese steel, and the unique heat treatment, our products possess strong wear resistance and long service life. | Mantle & Bowl Liner are the main wear part of cone crusher. We provide the matching products according to the customers’ machine type. The product mainly uses high manganese steel material, for example Mn14Cr2, Mn18Cr2, Mn22Cr2 and so on. | The main wearing parts of impact crusher are blow bar and impact plate, with special heat-treatment, the hardness of our blow bar can reach to HRC58~HRC63.

Our blow bars and impact plates are widely used on mining, construction, chemical, cement and metallurgical industry. Our impact parts have a service life 50~100% longer than those made of traditional high chromium iron. |

||

|

|

|

||

Crusher Hammer |

VSI Wear Parts |

Teeth Roller |

||

| Crusher Hammer such as clinker crusher hammer and raw material hammer are the core parts of hammer crusher. Our hammer crusher parts: crusher hammers use refining, vacuum casting, directional solid and etc technicals to increase the grain refinement and make the hammer performance achieve the best performance. | We Willingindustry supply VSI crusher wear parts such as guide plates, feed tubes, anvils and shoes, tail liners, center cones and so on. Because of the advanced process, all products go through in-process and final inspection.

The hardness is the most essential factor of the products. Our products possess high wear-resistance feature and long life time. |

Teeth Roller is the main wear part of roller crusher, our material is high manganese steel with tungsten, tin, chromium and other rare metals. Very wear-resistant and high temperature resistant with can reach to HRC58~HRC63.

Because of the advanced process, our teeth rollers contain a service life 50~100% longer than those made of traditional high chromium iron. |